Environmental Impacts of Lithium Mining and Extraction

Discover the environmental impacts of lithium mining and extraction, and how Lithium Harvest turns wastewater into a sustainable solution.

A Greener Future Starts with Smarter Lithium Extraction

The global push for renewable energy and the transition to electric vehicles have sent lithium demand soaring. It’s now a critical component in battery production. But behind the promise of a cleaner future lies a hard truth: traditional lithium mining is anything but clean.

Conventional methods like open-pit mining and brine evaporation take a heavy toll. They scar natural landscapes, drain scarce water supplies, pollute ecosystems with toxic chemicals, and release significant greenhouse gas emissions. Ironically, the race to build a more sustainable future is being held back by outdated and environmentally harmful extraction practices.

The problem is clear: if we continue relying on conventional lithium mining, we risk trading one environmental crisis for another. The toll is too high - it’s time for a smarter, more responsible approach.

At Lithium Harvest, we’re not just talking about sustainability - we’re building it. Our groundbreaking extraction technology transforms what was once considered waste – oilfield wastewater and geothermal brine - into a valuable, low-impact resource. By repurposing existing streams, we reduce carbon emissions, conserve freshwater, and set a new standard for sustainable lithium production.

In this blog post, we’ll examine the environmental impacts of traditional lithium mining and show how Lithium Harvest is helping to rewrite the rules.

Table of contents:

- The Environmental Tool of Lithium Mining

- Assessing the Carbon Impact - CO₂ Emissions in Lithium Mining Methods

- Technological Benchmark

- Technology Benchmark - Environmental Impact

- Redefining Green Lithium Extraction

- Slash EV Emissions Faster with Sustainable Lithium

- Revolutionizing Lithium Mining - The Sustainable Solution

The Environmental Toll of Lithium Mining

The hidden costs of traditional lithium mining: environmental consequences unveiled.

Traditional lithium mining carries major environmental downsides – often overlooked in the rush to build a cleaner energy future. While lithium is essential for EVs and renewable energy storage, the way it’s extracted today can come at a steep cost.

Here’s a closer look at the environmental impact of conventional lithium extraction methods:

-

Land & water degradation

Traditional lithium mining isn’t just about extracting a resource - it’s a major disruptor of the natural environment. The most common method, open-pit mining, involves stripping away massive amounts of soil and rock to reach lithium-rich ore. The result? Deforestation, soil erosion, and the destruction of critical habitats. Wildlife is displaced, ecosystems are disrupted, and natural recovery becomes a long, uphill battle.

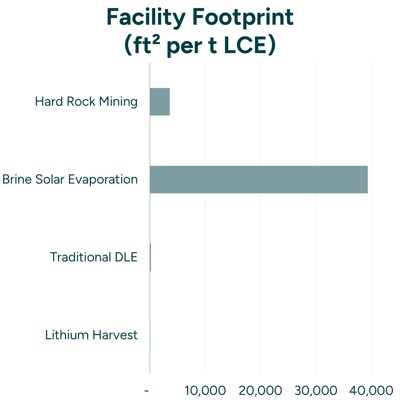

To put it into perspective: hard rock mining requires over 3,605 ft² of land per ton of lithium carbonate equivalent (LCE) - roughly the size of 0.68 football fields. That kind of land use leads to lasting damage to biodiversity and ecological balance when produced at scale.

And the impact doesn’t stop at the land - it also affects our water sources.

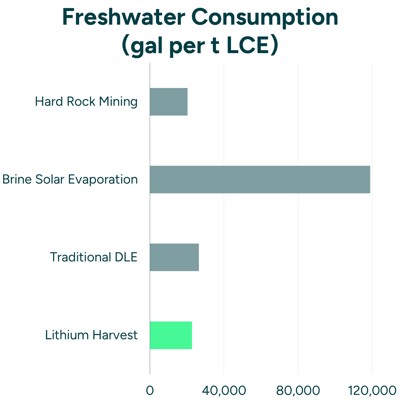

Conventional brine extraction methods pump huge volumes of water from underground aquifers to the surface, where it evaporates over months or even years. This process consumes vast amounts of water, often in regions already dealing with extreme water stress.

In Chile’s Salar de Atacama, one of the world’s key lithium production hubs, mining operations use up to 65% of the region’s water supply, putting intense pressure on both communities and ecosystems.

The contrast with Lithium Harvest’s approach couldn’t be more evident. We use ~81% less freshwater than traditional mining, saving ~96,148 gallons per ton of LCE. At 1,000 tpa, that’s ~96.1 million gallons a year (~364,000 m³) - about 146 Olympic pools - roughly 800 to 880 U.S. households’ annual use - or ~1.54 billion cups of coffee.

-

Water contamination

Chemical use is common in traditional lithium extraction, especially during the separation of lithium from other elements. But when these chemicals are not adequately managed, they can contaminate nearby water sources, harming aquatic life and threatening the water quality for surrounding communities.

Without effective wastewater treatment, the environmental consequences can be severe.

Responsible water management isn’t optional - it’s essential.

-

Greenhouse gas emissions

While lithium is essential for the clean energy transition, there is a harsh irony: traditional extraction methods are significant contributors to climate change. Conventional processes involve energy-intensive steps, such as high-temperature roasting, chemical processing, and a heavy reliance on fossil fuel-powered transportation and electricity. The result? A massive release of carbon dioxide and other greenhouse gases only worsens global warming.

The scale is staggering: The industry emits an average of 35.2 metric tons of CO₂ for every one metric ton of lithium produced. To put that in perspective, that’s the annual carbon footprint of about eight gasoline-powered cars, based on U.S. EPA data (4.6 metric tons CO₂ per car, per year).

Now compare that with Lithium Harvest’s approach.

Our carbon-neutral technology prevents up to 20.4 million kilograms (20,400 metric tons) of CO₂ for every 1,000 metric tons of lithium carbonate produced - equivalent to taking about 4,435 gasoline cars off the road for a year.

Cutting emissions in lithium extraction isn’t just a nice-to-have - it’s a necessity. And at Lithium Harvest, we’re proving that sustainable, profitable lithium production isn’t just possible - it’s going to happen.

-

Air pollution

Mining operations don’t just affect the land and water - they also impact the air we breathe.

Dust and particulate matter released during extraction can harm the respiratory health of nearby communities and wildlife. On top of that, fossil fuel-powered machinery and transport vehicles emit pollutants like nitrogen oxides and sulfur dioxide, contributing to poor air quality and long-term environmental damage.

Cleaner extraction methods mean cleaner air for people and the planet.

-

Energy consumption

Traditional lithium extraction requires enormous amounts of energy. Crushing, grinding, and chemical separation require massive amounts of electricity, much of which is still sourced from fossil fuels.

This reliance on coal and other high-emission energy sources significantly adds to the carbon footprint of lithium production, undermining the very environmental benefits that lithium is meant to support.

If we want truly clean energy systems, the way we produce lithium needs to be just as clean.

-

Soil contamination

Beyond water and air, lithium extraction can also take a toll on the soil.

Chemical residues from traditional processes can seep into the ground, disrupting the soil’s natural balance and harming plant life. Over time, this contamination can degrade soil fertility, reduce agricultural productivity, and damage local ecosystems.

It’s a hidden cost - but one that communities and ecosystems can’t afford to ignore.

-

Visual impact and aesthetics

While most conversations about lithium mining focus on carbon emissions and water use, the visual impact is often overlooked - yet it is a serious environmental concern.

Open-pit mines and massive evaporation ponds transform natural landscapes into barren, industrial zones. The damage isn’t just an eyesore - it’s often permanent. Once disturbed, these lands are rarely restored to their original state.

And the impact goes beyond the environment.

In regions where communities have deep cultural and spiritual ties to the land, these scars can represent loss and exploitation, not progress. They also threaten tourism, recreation, and the aesthetic value of natural areas.

To put it in perspective: solar evaporation uses ~39,352 ft² per ton of LCE - ~39.35 million ft² per 1,000 tons - which is about 903 acres (≈366 hectares), or roughly 683 American football fields (including end zones).

Now imagine trying to replant and restore that. The scale is staggering, and proper rehabilitation is rare.

Assessing the Carbon Impact - CO₂ Emissions in Lithium Mining Methods

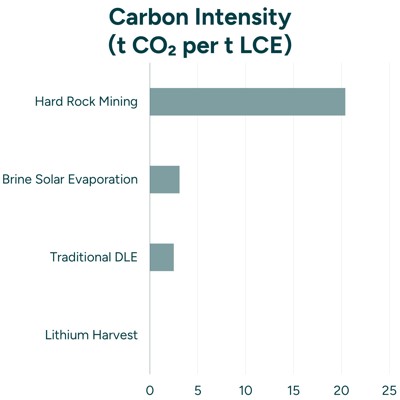

The push for lithium to power electric vehicles and renewable energy storage has a hidden cost: carbon emissions. Traditional lithium extraction methods, especially hard rock mining and brine evaporation, significantly contribute to climate change due to their energy-intensive processes and reliance on fossil fuels.

The carbon problem

Conventional lithium extraction is far from green. The process involves:

- High-temperature roasting of spodumene ore, requiring massive energy inputs, usually from coal or natural gas.

- Diesel-powered transport and infrastructure, including excavation, road construction, and water handling.

- Electricity from fossil-heavy grids drives additional emissions.

The result? The industry emits an average of 35.2 tonnes of CO₂ per tonne of lithium produced.

To put that in perspective:

- That’s like driving a gasoline-powered car around the entire Earth 1.5 times.

- Or the electricity usage of a U.S. household for over 5 years.

Now, scale that up: global lithium demand is expected to grow more than fourfold by 2035. If we continue to rely on traditional mining, our carbon footprint will be massive.

Lithium Harvest’s carbon-neutral solution

At Lithium Harvest, we’re changing the game with a carbon-neutral extraction process. For every 1,000 metric tons of lithium carbonate produced, we prevent ~20.4 million kilograms (20,400 metric tons) of CO₂ - equivalent to taking about 4,435 passenger cars off the road for a year, the annual energy use of ~2,660 U.S. homes, or growing ~340,000 tree seedlings for 10 years.

The message is clear: If we want a truly green energy transition, we can’t keep relying on carbon-intensive methods to fuel it. With more innovative, cleaner extraction, we can meet tomorrow’s demand without compromising the planet.

Solar Evaporation Brine Extraction |

Hard Rock Mining |

|

|---|---|---|

| Lithium carbonate | Approximately 2.8 tonnes of CO₂ emissions per tonne of LCE | Around 9.6 tonnes of CO₂ emissions per tonne of LCE |

| Lithium hydroxide | Emissions are about 5.7 tonnes of CO₂ per tonne of LCE | Significantly higher at approximately 17.1 tonnes of CO₂ per tonne of LCE |

Solar Evaporation Brine Extraction

Hard Rock Mining

Technological Benchmark

Our innovation surges ahead of competitors.

The lithium industry has long depended on outdated, environmentally harmful extraction methods. But that’s changing.

Technological innovation is reshaping what is possible, and at Lithium Harvest, we’re not just keeping up - we’re setting the standard.

We’re raising the bar for efficiency, sustainability, and environmental responsibility - proving that clean lithium production can be fast, profitable, and planet-friendly.

Lithium Harvest Solution |

Traditional DLE |

Solar Evaporation Brine Extraction |

Hard Rock Mining |

|

|---|---|---|---|---|

| Lithium feedstock | Produced water/geothermal brine | Continental brine | Continental brine | Rock / spodumene |

| Project implementation time | 12-18 months | 5-7 years | 13-15 years | 10-17 years |

| Lithium carbonate production time | 2 hours | 2 hours | 13-24 months | 3-6 months |

| Lithium yield | >95% | 80-95% | 20-50% | 40-70% |

| Average footprint per mt of LCE | 61 ft² | 172 ft² | 39,352 ft² | 3,605 ft² |

| Environmental impact | Minimal | Minimal | Soil and water contamination | Soil and water contamination |

| Freshwater consumption per mt of LCE | 22,729 gallons | 26,417 gallons | 118,877 gallons | 20,341 gallons |

| CO₂ footprint per mt of LCE | Neutral | 2.5 tonne | 3.1 tonne | 20.4 tonne |

Lithium Harvest Solution

Traditional DLE

Solar Evaporation Brine Extraction

Hard Rock Mining

At Lithium Harvest, we’re proving that lithium extraction can be efficient, profitable, and sustainable - turning waste into a valuable resource and cutting the environmental cost of clean energy.

Technology Benchmark - Environmental Impact

Rethinking lithium’s footprint

Traditional lithium extraction methods - particularly hard-rock mining and solar evaporation - come with a heavy environmental cost. From excessive carbon emissions and unsustainable water use to large-scale land disruption, the damage is undeniable. At Lithium Harvest, we’re offering a faster, cleaner way forward - putting efficiency and environmental responsibility on equal footing.

Redefining the carbon footprint

We run a carbon-neutral extraction process that cuts emissions across the value chain. By co-locating with existing infrastructure, avoiding long-haul transport to secondary refining, and using a low-pressure, low-energy system powered by renewables, we reduce both direct and indirect emissions.

Result: We prevent ~20.4 million kg CO₂ (20,400 t) for every 1,000 t LCE produced. That’s roughly ~4,435 passenger cars off the road for a year, or ~2.3 million gallons of gasoline not burned.

Minimizing land sse

No evaporation ponds. No sprawling greenfield mines. Our facilities are modular, compact, and co-located at oilfield or geothermal sites for fast deployment and minimal disruption.

Context: Solar evaporation requires ~39,352 ft² per ton of LCE - ~39.35 million ft² (≈903 acres) per 1,000 t - roughly 683 American football fields. Our surface footprint is measured in acres, not hundreds of acres.

Water conservation: A circular approach

Water is critical - and we treat it that way. We recirculate process water and rely on minimal freshwater.

Result: We use ~81% less freshwater than traditional mining.

That’s ~96,148 gallons saved per ton of LCE. At 1,000 t, that’s ~96.1 million gallons/year (≈364,000 m³) saved - roughly ~800–880 U.S. households’ annual water use.

Redefining Green Lithium Extraction

Lithium Harvest vs. traditional lithium mining.

Slash EV Emissions Faster with Sustainable Lithium

Discover how we reduce battery life cycle emissions by 57%

Revolutionizing Lithium Mining - The Sustainable Solution

Inefficiencies, environmental damage, and a massive carbon footprint plague traditional lithium mining. As global demand skyrockets, the industry faces a critical question:

Can we truly call lithium a clean energy resource if extracting it harms the planet?

At Lithium Harvest, we believe the answer can - and must - be yes.

Our revolutionary extraction technology minimizes environmental impact while actively supporting a cleaner, more sustainable energy future.

Repurposing oilfield wastewater & geothermal brine

We use Direct Lithium Extraction (DLE) combined with advanced water treatment to recover lithium from oilfield wastewater and geothermal brine – previously untapped, often discarded resources.

This approach allows us to:

- Minimize freshwater use

- Reduce the environmental footprint of wastewater disposal

- Promote efficient, responsible water management

Efficiency & emissions - redefined

Our sustainable process eliminates the need for large-scale land disruption, helping reduce:

- Deforestation and habitat loss

- Energy consumption and CO₂ emissions

The result? A dramatically lower carbon footprint per metric ton of lithium carbonate, making our solution a true enabler of the clean energy transition.

Circular economy in action

Sustainability at Lithium Harvest goes beyond the extraction process. By embracing circular economy principles, we:

- Turn waste into value

- Minimize pollution and excess waste

- Create a more resource-efficient and climate-resilient supply chain

A smarter path forward

The environmental damage caused by traditional lithium mining isn’t just real - it’s avoidable. With Lithium Harvest’s solution, it’s possible to meet rising lithium demand without sacrificing the planet.

By repurposing brines, improving efficiency, and building circular systems, we’re not just reducing harm - we’re driving the green energy transition forward.

Sustainability isn’t a compromise - it’s a competitive advantage. Let’s lead the way.

Lithium Extraction

You may also be interested in: