Battery-Grade Lithium Compounds

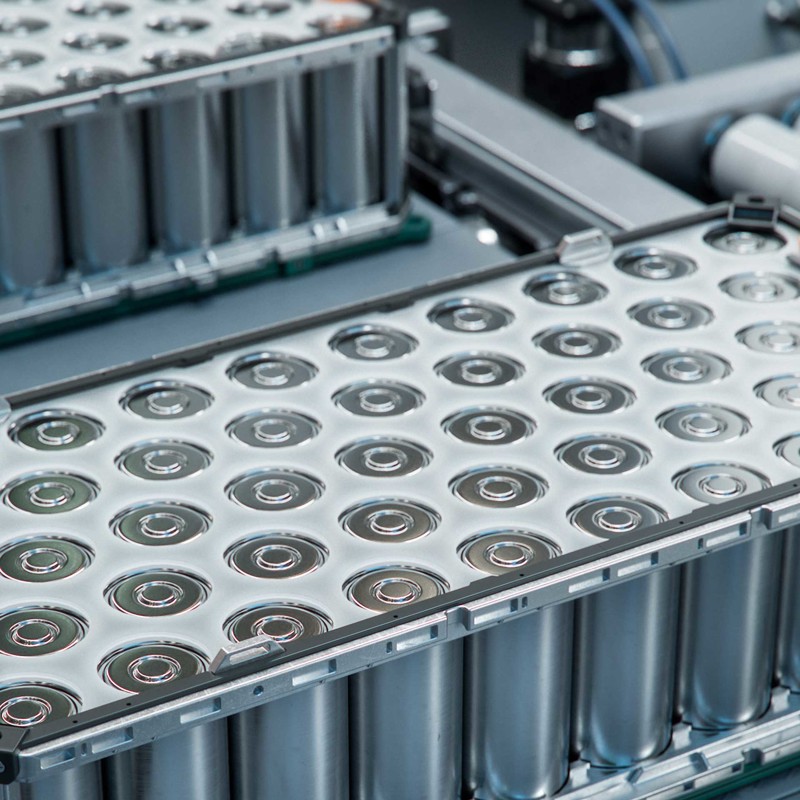

Power your batteries with lithium carbonate and hydroxide made from wastewater - sustainably sourced, cost-effective, and designed to scale.

Discover sustainable lithium

Rethinking Critical Mineral Supply

Pits and ponds are slow, heavy, and concentrated risks. The next supply pathway is already flowing.

Traditional lithium supply was built on pits, ponds, and long timelines. It’s slow to scale, heavy on land and water, and concentrates supply risk in a few regions and routes - the opposite of what the battery value chain needs as demand rises and supply chains localize.

Meanwhile, a new resource stream is already moving every day: produced water and geothermal brines. These brines are typically treated as a cost, a constraint, or simply “wastewater” - even though they can contain lithium and other valuable battery materials.

Lithium Harvest is building a different pathway: surface-based, modular extraction and local refining that turns existing brine flows into critical battery materials - faster, cleaner, and more cost-effective than traditional mining, designed to strengthen local supply.

What we deliver

- Battery-grade lithium carbonate (Li₂CO₃)

- Battery-grade lithium hydroxide (LiOH)

A Better Way to Supply Lithium

Here’s the difference between conventional lithium supply and Lithium Harvest’s approach - focused on what matters to the battery value chain: speed, footprint, resilience, and cost competitiveness.

Lithium Harvest Solution |

Traditional DLE |

Solar Evaporation Brine Extraction |

Hard Rock Mining |

|

|---|---|---|---|---|

| Lithium feedstock | Produced water/geothermal brine | Continental brine | Continental brine | Rock / spodumene |

| Project implementation time | 12-18 months | 5-7 years | 13-15 years | 10-17 years |

| Lithium carbonate production time | 2 hours | 2 hours | 13-24 months | 3-6 months |

| Lithium yield | >95% | 80-95% | 20-50% | 40-70% |

| Average footprint per mt of LCE | 61 ft² | 172 ft² | 39,352 ft² | 3,605 ft² |

| Environmental impact | Minimal | Minimal | Soil and water contamination | Soil and water contamination |

| Freshwater consumption per mt of LCE | 22,729 gallons | 26,417 gallons | 118,877 gallons | 20,341 gallons |

| CO₂ footprint per mt of LCE | Neutral | 2.5 tonne | 3.1 tonne | 20.4 tonne |

| Average invested capital per mt of LCE | $17,100 | $62,500 | $34,000 | $60,000 |

| Average cost per mt of LCE | $3,647 | $6,000 | $6,400 | $7,000 |

| Supply resilience | Distributed, domestic/nearby fluids | Concentrated geographies; long chains | Concentrated geographies; long chains | Concentrated geographies; long chains |

Lithium Harvest Solution

Traditional DLE

Solar Evaporation Brine Extraction

Hard Rock Mining

If You Sourced 15,000 t LCE From Us, What Would Change?

One plant, one year, and a very different footprint than traditional mining. Compare the pathways per tonne, then scale it to your demand (example: 15,000 t LCE per year).

Traditional Mining (Per t LCE) |

Lithium Harvest Solution (Per t LCE) |

Savings vs Traditional (Per t LCE) |

Example at 15,000 t LCE - Equivalent to… |

|

|---|---|---|---|---|

| Land footprint | 172 - 39,352 ft² | 61 ft² | 111 - 39,291 ft² | 1,665,000 - 589,365,000 ft² saved - equivalent to 22 - 7,669 football pitches. |

| Freshwater consumption | 26,417 - 118,877 gallons | 22,729 gallons | 3,688 - 96,148 gallons (~14 - 364 m³) | 55,320,000 - 1,442,220,000 gallons saved - equivalent to ~2.09 - 54.59 billion cups of coffee. |

| CO₂ footprint | 2.5 - 20.4 t CO₂ | Zero carbon (if possible) | 2.5 - 20.4 t CO₂ avoided | 37,500 - 306,000 t CO₂ avoided - equivalent to ~8,152 - 66,522 passenger cars off the road for a year |

Traditional Mining (Per t LCE)

Lithium Harvest Solution (Per t LCE)

Savings vs Traditional (Per t LCE)

Example at 15,000 t LCE - Equivalent to…

Supply Assurance, Built to Scale

Modular plants, local build-out, and a partner model designed for long-term reliability - and to perform through lithium price cycles and demand swings.

Lithium Harvest isn’t selling a concept. We’re building a repeatable supply pathway designed to deliver reliable lithium compounds at scale, with economics built for volatile markets.

How we scale supply

- DBOO + modular scale: We design, build, own, and operate modular plants that can be expanded with additional capacity as demand grows.

- Local build-out: We co-locate where brines already flow, strengthening local supply and reducing logistics complexity.

Our rollout plan

- Target first production: 2027

- Full rollout scale: 50,000+ t LCE per year at full build-out

Why does this stay resilient through price cycles?

- Low CapEx per t LCE: Our modular, co-located approach is designed to reduce capital intensity - improving resilience and enabling capacity additions as demand grows.

- Bottom-decile OpEx positioning: We operate well inside the bottom decile of peers’ operating costs with meaningful headroom to market-clearing cost bands. That cost headroom helps keep supply reliable when prices fluctuate and demand shifts.

Let’s not forget what downcycles do: our analysis suggests that under 2024-2025 market conditions, ~11-13 mostly high-CapEx hard-rock projects (~150-282 kt LCE/yr) have been delayed or cancelled.

Reliable lithium supply isn’t just about chemistry - it’s about a model built to deliver through the cycles.

Why Choose Lithium Harvest?

A better lithium partner - built for your goals and the planet.

Four reasons our lithium compounds pathway is built to win: domestic scale, fast ramp, defensible sustainability, and cost resilience through price swings.

-

Domestic, scalable supply

Stop shipping value around the world. We extract and refine lithium at the source, where brines already flow, and scale through a modular build-out. That shortens supply chains, cuts shipping exposure, and reduces the geopolitical roulette that keeps battery procurement teams up at night.

-

Fast-to-market volumes

Battery demand moves in quarters. Conventional mining moves in decades. Our projects are designed to come online in 12-18 months, then expand capacity in steps as demand grows. Traditional mines take up to 17 years from discovery to production.

Result: scalable volumes without betting your roadmap on a single mega-project.

-

Cleaner lithium that protects your brand

“Sustainable” only counts if you can defend it under scrutiny. Our pathway is designed to have a smaller footprint than pits and ponds, giving you a cleaner sourcing story when customers, auditors, and regulators ask detailed questions.

-

Cost leadership for reliable supply during market swings

Downcycles don’t just lower prices - they kill supply. High-CapEx, high-cost projects get delayed, cancelled, or quietly shelved, and future supply tightens at the worst time. Our model is built for cost competitiveness, so supply stays reliable when the market turns.

The world’s most sustainable lithium

-

Domestic supply pathway: Local extraction and refining to shorten supply chains and reduce geopolitical and shipping risk.

-

Fast-to-market, modular scale: Designed to come online in 12-18 months and expand capacity step-by-step as demand grows.

-

Cost resilience through cycles: Built for cost competitiveness so supply stays reliable when lithium prices swing.

-

Lower-footprint pathway: Leading the way in eco-friendly lithium extraction, we provide some of the world's most sustainable lithium for a greener future.

Take our brochure with you!

Download PDF, 966.66 KBLet’s Talk Lithium Supply

Tell us what you’re building - chemistry, timeline, and volumes. We’ll get back fast.