EV Greenhouse Gas Emission Breakeven Point

Learn how sustainable lithium mining can cut EV greenhouse gas emissions breakeven point 5.7x faster.

EVs vs. ICE - The Challenges We Face

Internal combustion engine vehicles (ICEVs) and electric vehicles (EVs) are two of the most popular types of vehicles on the market today. ICEVs run on gasoline, diesel, or other fossil fuels, while EVs run on electricity stored in rechargeable batteries. While both vehicle types have their pros and cons, interest in EVs is growing rapidly as a more sustainable and eco-friendly alternative.

One of the biggest challenges for EVs is their reliance on critical minerals to produce lithium-ion batteries. Lithium is a key component, and as EV demand surges, so does the need for lithium. Although lithium is relatively abundant, its extraction and processing can lead to environmental issues such as water scarcity and pollution.

That's why there's growing interest in sustainable lithium extraction methods. These aim to reduce the environmental impact of lithium production by turning wastewater into high-value minerals. New technologies promise to reduce water use, prevent damage to habitats and biodiversity, and minimize waste and carbon emissions. Some companies are also exploring the use of recycled lithium from old batteries to help ease the pressure on mining.

Both ICEVs and EVs come with trade-offs. ICEVs may offer longer range and lower upfront costs, but EVs are becoming more affordable and come with lower operating costs and fewer maintenance needs. Still, the rising demand for lithium-ion batteries highlights the need for more responsible extraction methods. Fortunately, with the rise of innovative and sustainable lithium technologies, it's possible to shrink the environmental footprint of battery production and drive toward a cleaner future.

How EVs Reduce the Environmental Impact of Transportation

Electric vehicles (EVs) are leading a revolution on the road, driving us toward a greener future. These high-tech EVs aren't just incredible - they're game-changers in cutting transportation's environmental footprint, especially greenhouse gas (GHG) emissions. The shift from internal combustion engine (ICE) vehicles to EVs is a critical step in the global fight against climate change and air pollution.

Slashing emissions on a global scale

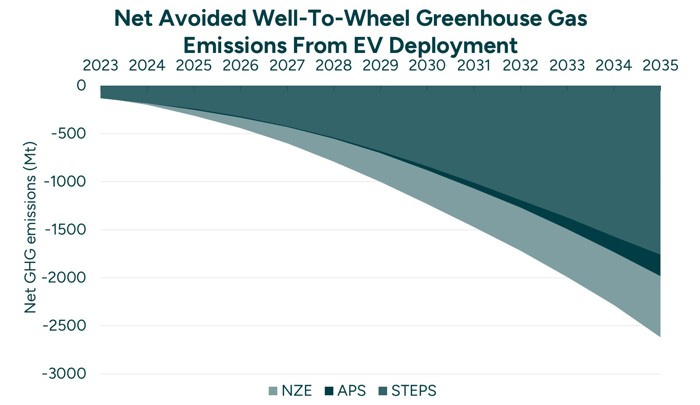

Imagine cutting billions of tons of CO₂ emissions - sounds pretty good, right? According to the International Energy Agency (IEA), widespread EV adoption could prevent around 2.6 gigatons of CO₂ emissions globally by 2035. That's like taking millions of cars off the road forever. Thanks to the increasing rollout of EVs across major markets, supported by strong policy measures and rapid technological improvements, this vision is becoming a reality.

In the U.S., for example, battery electric vehicles (BEVs) already show lifecycle emissions that are 45% to 65% lower than plug-in hybrids (PHEVs), hybrid vehicles (HEVs), and traditional ICE vehicles. Over a medium-sized BEV's life, that translates to around 50 tonnes of CO₂-equivalent savings. Talk about making a real difference with your daily commute!

Reducing lifecycle emissions

The environmental benefits of EVs extend far beyond just reducing tailpipe emissions. The main environmental footprint of an EV comes during its production, especially in building lithium-ion batteries, which is an energy-intensive process. But even when factoring that in, EVs still come out ahead.

According to multiple lifecycle assessments (including work by Transport & Environment), a medium-sized EV emits around 16.9 tons of CO₂ over its lifetime, compared to 54.3 tons for a gasoline vehicle. That's nearly a 70% reduction. And while EVs start with a slightly higher carbon cost due to battery production, they hit the break-even point after just 11,335 mi/18,243 km of driving (sources: ICCT, Transport & Environment, BloombergNEF, and IEA).

Sustainable advancements in battery technology

Battery technology is moving fast, and that's good news for sustainability. Lithium iron phosphate (LFP) batteries, for example, emit about one-third less CO₂ per kilowatt-hour than high-nickel NMC batteries. These improvements help reduce the environmental footprint of EVs and make them even more viable in the long term. Governments are also getting behind cleaner batteries, with policies like carbon tariffs and EV subsidies increasingly tied to emissions performance.

The path forward

EVs are already reshaping the environmental impact of transportation, but there's still work to be done. The key is decarbonizing the entire EV lifecycle, especially battery manufacturing and raw material extraction. As battery technology, supply chains, and clean energy infrastructure improve, EVs will only become greener, faster, and more accessible.

The clean transportation future isn't just possible - it's already on the road.

And We Can Make It Even Cleaner

The electric vehicle (EV) industry is poised for a revolution, and Lithium Harvest is leading the charge. Our innovative approach is not only changing the game but also redefining the lithium market. As the world shifts toward cleaner transportation, the sustainability of EV battery supply chains becomes critical. Lithium Harvest steps in, offering a groundbreaking solution that boosts EV sustainability and reduces their carbon footprint.

Revolutionizing lithium extraction

At the core of our environmental commitment is our patented lithium extraction solution, engineered to minimize impact. Unlike traditional methods that are resource-intensive and disruptive, our approach extracts lithium from oilfield wastewater and geothermal brine, turning a waste byproduct into a valuable, clean energy resource.

By integrating our sustainable lithium extraction solution, we estimate that battery lifecycle emissions could be cut by up to 57%. That reduction has a real-world impact. An EV powered by our lithium could reach its greenhouse gas breakeven point after just 1,982 mi/3,190 km - 5.7 times faster than the industry average of 11,335 mi/18,243 km. This breakthrough helps EVs outperform fossil-fuel vehicles faster, making them an even stronger choice for drivers and policymakers.

Setting a new standard in sustainable lithium production

This isn't just about reducing emissions - it's about rethinking how lithium should be produced. Our method is one of the most sustainable in the industry, delivering standout environmental benefits. Compared to traditional sources, our process can save up to 17.6 m³ of water and free up to 141 m² of land for each EV battery produced.

These aren't just statistics - they represent a tangible shift toward cleaner manufacturing that respects the planet's resources. By minimizing water use and avoiding land disruption, we align our operations with the highest standards of environmental responsibility, ensuring EV growth doesn't come at the expense of the ecosystems we're all trying to protect.

ICE |

EV (Traditional Mining) |

EV (Lithium Harvest) |

Impact |

|

|---|---|---|---|---|

| Battery CO₂ | - | 4.7 tonne | 2.0 tonne | -57% |

| Lifetime CO₂ | 54.3 tonne | 16.9 tonne | 14.2 tonne | -16% (-74% vs ICE) |

| GHG breakeven vs ICE | - | 11,335 mi/18,243 km | 1,982 mi/3,190 km | 5.72× sooner - 83% fewer km |

| Water saved per car | - | - | 17.6 m³ | >90 water recycling/reuse |

| Land saved per car | - | - | 141 m² | No new pits or ponds |

ICE

EV (Traditional Mining)

EV (Lithium Harvest)

Impact

Still Wondering if EVs Are Really Better for the Environment?

Watch this short clip from CERAWeek 2025, where our CEO, Sune Mathiesen, breaks down the real emissions impact of EVs - and how Lithium Harvest is helping make them even greener.

The Car Industry Is Moving Toward EVs

The automobile industry is rapidly shifting toward electric vehicles (EVs) as consumer demand grows for cleaner, more sustainable transportation options. According to the IEA, EVs are expected to make up 50% of all cars sold globally by 2035. The global EV fleet is projected to grow twelvefold to 585 million by 2035, with an average annual growth rate of 24% from 2023 to 2035.

Governments worldwide are helping accelerate this shift with supportive policies, such as tax incentives, rebates, and subsidies for EV purchases and mandates for automakers to boost low-emission vehicle production.

Major automakers are also making bold moves. Some plan to phase out gas and diesel vehicles entirely. Volvo has committed to producing only electric vehicles by 2035, while General Motors aims to go all-electric by 2040.

This momentum marks a significant turning point for the auto industry, one that is driving us toward a more sustainable and environmentally conscious future.

Before 2030 |

Before 2035 |

2040-2025 Long View |

|

|---|---|---|---|

| Bentley | - | Stop ICE sales shortly after 2035 | - |

| Volkswagen | ≥80% EV sales in EU; 55% in NA | Stop ICE sales in EU | Group-wide carbon-neutrality by 2050 |

| Toyota | 55 electrified models on sale (2025 target) | 50% ZEV sales worldwide | - |

| Volvo Cars | 50% EV/PHEV mix (2025 target) | 100% EV & PHEV only | - |

| Jaguar | 100% BEV brand by 2025 | - | - |

| Mercedes-Benz | 50% electrified sales | - | - |

| Subaru | 50% electrified sales | - | - |

| Hyundai-Kia | - | 100% electrified sales in Europe | Close to 100% electrified globally by 2040 |

| Nissan | 100% BEV sales in Europe | - | Carbon-neutrality across PLC by 2050 |

| General Motors | - | - | End ICE sales globally by 2040 |

| Renault Group | 100% EV sales in Europe | - | Carbon-neutral group by 2050 |

| Mazda | 25-40% EV share | - | Carbon-neutral by 2050 |

| BMW Group | EVs ≈50% of deliveries | - | End ICE sales “well before 2050” |

| Honda | EV+FCEV = 40% global sales | - | 100% EV+FCEV sales globally by 2040 |

| Ford Motor | ≥50% global sales EV or PHEV | - | - |

| Mitsubishi | - | 100% electrified sales | - |

| Suzuki | 80% BEV sales in Europe | - | - |

Before 2030

Before 2035

2040-2025 Long View

Countries are Banning ICE Vehicles

Phase-out year 2030 |

Phase-out year 2035 |

Phase-out year 2040 |

Phase-out year 2050 |

|

|---|---|---|---|---|

| Countries/jurisdictions mandating 100% zero-emission new-car sales | Norway (2025), Denmark, Ireland, Iceland, Sweden, Israel, Netherlands, Singapore, Slovenia | United Kingdom, Cabo Verde, China, Japan, Canada, California (U.S.), Rest of the EU, South Korea, Thailand | France, Spain, Taiwan, Sri Lanka, Vietnam | Costa Rica |

Phase-out year 2030

Phase-out year 2035

Phase-out year 2040

Phase-out year 2050

A Circular and Responsible Battery Value Chain for EVs

We recognize that creating a circular and responsible battery value chain isn't just a goal - it's a necessity for meeting global climate targets. As the auto industry rapidly shifts to electric vehicles, building a truly sustainable battery supply chain has never been more critical. EVs promise a cleaner future, but to deliver on that promise, every part of the battery lifecycle needs to be examined and optimized for sustainability.

Our work isn't just about today - it's about the future. By transforming how lithium is extracted, we're laying the foundation for a cleaner, more responsible industrial landscape that can stand the test of time. This isn't just about improving EV production - it's about shaping the future of the planet.

We believe the choices we make now will define the world we leave behind. By working with industry partners, policymakers, and consumers, we can raise the bar for the lithium industry and make EVs not just cleaner but one of the key pillars of a truly sustainable future.

Energy Transition

You may also be interested in: