Environmental Impacts of Lithium Mining and Extraction

Discover the environmental impacts of lithium mining and extraction, and how Lithium Harvest turns wastewater into a sustainable solution.

Introduction

The growing demand for renewable energy and the transition to electric vehicles have significantly increased the need for lithium, a vital component in producing batteries. However, the extraction and processing of lithium have raised concerns about their environmental impact. This blog post aims to explore the environmental consequences of lithium mining and extraction while highlighting Lithium Harvest's innovative solution, which utilizes wastewater as a sustainable approach.

It is important to note that the severity of these environmental impacts can vary depending on the location, mining practices, and regulatory measures in place. However, developing sustainable alternatives to traditional lithium extraction, such as the approach proposed by Lithium Harvest, is crucial to mitigate these environmental consequences and pave the way for a greener and more responsible lithium industry.

Table of contents:

- The Environmental Tool of Lithium Minings

- Assessing the Carbon Impact: CO₂ Emissions in Lithium Mining Methods

- Technological Benchmark

- Technology Benchmark - Environmental Impact

- Redefining Green Lithium Extraction

- Slash EV Emissions Faster with Sustainable Lithium

- Revolutionizing Lithium Mining: The Sustainable Solution

The Environmental Toll of Lithium Mining

The hidden costs of traditional lithium mining: environmental consequences unveiled.

Traditional lithium mining comes with significant environmental costs, from degrading land and water resources to contributing to air pollution and climate change. In the sections below, we delve into the hidden environmental consequences of lithium mining, revealing the challenges we must address to make our pursuit of renewable energy truly sustainable.

-

Land & Water Degradation

Traditional lithium mining is more than just a resource extraction process – it is a significant disruptor of our natural world. The most common method, open-pit mining, requires vast amounts of land, leading to deforestation, soil erosion, and the destruction of critical habitats. These massive excavations not only displace wildlife but also strain local ecosystems. The thirst for lithium does not stop at the land; it also extends to our water sources. Large quantities of water are required, often depleting local supplies and putting immense pressure on already fragile ecosystems.

-

Water Contamination

Extracting lithium can involve using hazardous chemicals to separate it from other elements. When not carefully managed, these chemicals can seep into nearby water bodies, turning rivers, streams, and groundwater into toxic channels. The ripple effects are profound—biodiversity suffers, aquatic life is threatened, and communities that depend on clean water are left vulnerable.

-

Greenhouse Gas Emissions

Ironically, the quest for materials essential to renewable energy is contributing to the very problem it is meant to solve - climate change. Lithium extraction is an energy-hungry process, requiring high-temperature roasting, extensive use of fossil fuels for transportation, and electricity generation. The result? A significant release of carbon dioxide and other greenhouse gases further exacerbates global warming.

-

Air Pollution

Mining operations do not just scar the earth; they also pollute the air. Dust and particulate matter kicked up during extraction can lead to respiratory problems for both humans and wildlife in nearby areas. Moreover, the heavy reliance on diesel-powered machinery and vehicles releases nitrogen oxides and sulfur dioxide into the atmosphere, contributing to air pollution and acid rain, with far-reaching consequences for environmental and human health.

-

Energy Consumption

The energy demands of traditional lithium extraction are staggering. Crushing, grinding, and chemical separation processes require vast amounts of electricity, much of which is sourced from non-renewable fossil fuels. This reliance on coal and other polluting energy sources increases the carbon footprint of lithium production, undermining the environmental benefits of the end products that rely on this mineral.

-

Soil Contamination

The chemicals used in lithium extraction do not just contaminate water - they also degrade the soil. When these substances seep into the ground, they disrupt natural ecosystems, harm soil fertility, and hinder vegetation growth. The result is a cascade of negative impacts, from reduced agricultural productivity to further degradation of already strained ecosystems.

-

Visual Impact and Aesthetics

Finally, the visible aftermath of lithium mining is that open-pit operations leave lasting scars on the landscape. These gaping wounds in the earth mar the natural beauty of the environment, impacting tourism, recreation, and cultural values tied to the land. The aesthetic damage is more than just a visual blight; it is a reminder of the heavy environmental toll that comes with our demand for lithium.

Assessing the Carbon Impact: CO₂ Emissions in Lithium Mining Methods

Lithium Harvest is leading the charge toward a sustainable future with our carbon-neutral approach, which is especially crucial considering the substantial CO₂ emissions in the lithium mining industry. On average, the industry emits approximately 35.2 tonnes of CO₂ per tonne of Lithium. To put this into perspective, traditional methods of lithium extraction emit significant CO₂.

In this context, Lithium Harvest's commitment to a carbon-neutral process is not just an innovation; it's a necessary step towards a greener and more responsible lithium mining industry. Learn more about our carbon footprint in the section below.

Solar Evaporation Brine Extraction |

Hard Rock Mining |

|

|---|---|---|

| Lithium carbonate | Approximately 2.8 tonnes of CO₂ emissions per tonne of LCE | Around 9.6 tonnes of CO₂ emissions per tonne of LCE |

| Lithium hydroxide | Emissions are about 5.7 tonnes of CO₂ per tonne of LCE | Significantly higher at approximately 17.1 tonnes of CO₂ per tonne of LCE |

Solar Evaporation Brine Extraction

Hard Rock Mining

Technological Benchmark

Our Innovation Surges Ahead of Competitors

Lithium Harvest Solution |

DLE from Brine |

Solar Evaporation Brine Extraction |

Hard Rock Mining |

|

|---|---|---|---|---|

| Feedstock | Produced water | Continental brine | Continental brine | Rock / spodumene |

| Project implementation time | 12-15 months | 5-7 years | 13-15 years | 8-10 years |

| Lithium carbonate production time | 2 hours | 2 hours | 2-3 years | 3-6 months |

| Lithium yield | >95% | 80-95% | 20-40% | 6-7% |

| Average footprint per 1,000 mt LCE | 1.4 acres | 1.4 acres | 65 acres | 115 acres |

| System design | Modular and mobile | Mobile / stationary | Stationary | Stationary |

| Environmental impact | Minimal | Minimal | Soil- and water contamination | Soil- and water contamination |

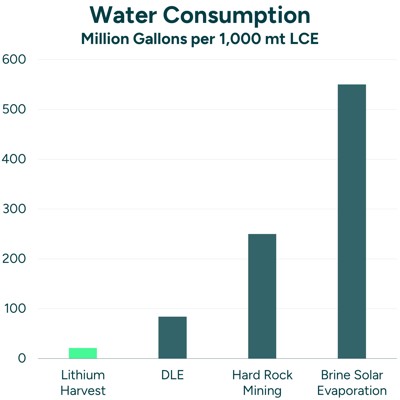

| Water consumption per 1,000 mt LCE | 20 million gallons | 80 million gallons | 550 million gallons | 250 million gallons |

| CO₂ footprint per 1,000 mt LCE | Neutral | 1.5 million kg | 5 million kg | 15 million kg |

Lithium Harvest Solution

DLE from Brine

Solar Evaporation Brine Extraction

Hard Rock Mining

Technology Benchmark - Environmental Impact

Redefining Carbon Footprint in Lithium Extraction

Lithium Harvest is revolutionizing the industry with our environmentally conscious approach, significantly reducing the carbon footprint of lithium extraction. Our unique method eliminates the need for transportation to secondary refining sites. We proudly utilize solar power as our primary energy source, further reducing our environmental footprint. With our low-pressure, low-energy solution, we are also offsetting carbon savings from efficient water handling, making a significant positive impact on the environment.

Minimizing Facility Footprint: A Step Towards Eco-Friendly Practices

Our commitment to the environment extends to our facility's footprint. Lithium Harvest's operations are co-located with produced water treatment facilities, ensuring a minimal environmental impact. Our facilities are designed to be modular and compact, making them easy to integrate and fast to deploy - there is no need for expansive ponds and pipelines. This approach not only saves space but also protects the surrounding environment and wildlife, ensuring no additional environmental disturbance.

Water Conservation: Pioneering Sustainable Practices

At Lithium Harvest, water conservation is a top priority. We proudly boast that over 90% of the water used in our process is reused, emphasizing our commitment to sustainable practices. Our operations don't almost consume fresh water, ensuring that local water resources remain unpolluted and undisturbed. Additionally, our process does not produce additional waste products, showcasing our dedication to preserving the planet's most precious resource.

Redefining Green Lithium Extraction

Lithium Harvest vs. Traditional Lithium Mining

Slash EV Emissions Faster with Sustainable Lithium

Discover how we reduce battery life cycle emissions by 47%

Revolutionizing Lithium Mining: The Sustainable Solution by Lithium Harvest

At Lithium Harvest, we recognize the urgent need to address the environmental challenges posed by traditional lithium mining. Our cutting-edge technology provides a sustainable alternative that transforms waste into a valuable resource, mitigating the adverse environmental impacts of extraction. Here's why our approach stands as the most sustainable solution in comparison to traditional mining methods:

- Repurposing Oilfield Wastewater: Lithium Harvest leverages proven Direct Lithium Extraction (DLE) technology combined with advanced water treatment to extract lithium from oilfield wastewater. By repurposing this previously discarded water, we minimize freshwater consumption and reduce the environmental footprint associated with wastewater disposal. This approach contributes to efficient water management and conservation.

- Resource Efficiency and Carbon Footprint Reduction: Our sustainable extraction process eliminates the need for extensive land disturbance, minimizing deforestation and soil degradation. Furthermore, our technology significantly reduces energy consumption and associated carbon emissions compared to traditional mining methods. This produces a substantially lower carbon footprint for each metric ton of lithium carbonate.

- Circular Economy and Waste Reduction: Lithium Harvest's commitment to sustainability extends beyond extraction. We embrace the principles of the circular economy by transforming waste materials into valuable resources. By effectively utilizing oilfield wastewater, we reduce pollution and minimize waste generation, fostering a more efficient and environmentally responsible approach.

The environmental impacts of traditional lithium mining are undeniable, necessitating a paradigm shift towards sustainable alternatives. Lithium Harvest's cutting-edge technology represents the most sustainable solution available, addressing the ecological concerns associated with traditional mining methods. By repurposing oilfield wastewater, prioritizing resource efficiency, and embracing circular economy principles, we provide a path to meet the global demand for lithium while minimizing environmental harm. Together, let us drive the green energy revolution forward with a commitment to sustainability and a cleaner, more sustainable future.

Lithium Extraction

You may also be interested in: