Our Technology

Our sustainable, patented technology delivers faster, cost-effective lithium extraction with minimal environmental impact - we take it to the next level.

Discover our lithium extraction technology

What Sets Our Technology Apart

-

>95% Lithium Recovery

High extraction efficiency from brines — maximizing value from every drop -

Low-Energy, Low-Pressure Process

Reduces operating costs and carbon footprint. Solar-compatible setup -

Battery-Grade Lithium Output

High-purity lithium compounds that meet the most stringent industry standards -

Lithium in Hours, Not Years

Rapid extraction – no long lead times -

Modular & Scalable

Fast deployment. Easily adapted to site conditions. No large infrastructure is needed -

Built for Sustainability

One of the world’s most sustainable lithium extraction technologies

Rethinking Critical Minerals Supply

The status quo can’t keep up. But you can.

Governments and companies are racing to secure critical minerals like lithium — but the traditional path is flawed.

Current strategies rely on remote, high-cost regions with limited infrastructure, long permitting timelines, and complex logistics. Traditional lithium mining methods — such as hard rock mining and evaporation ponds — take years to deliver, require massive land and water use, and carry significant environmental and social challenges.

The result? Rising supply chain risks, higher emissions, and uncertain delivery.

Meanwhile, a better solution has been overlooked for decades: Oilfield wastewater and geothermal brine — already in use within energy operations — contain untapped lithium and other critical minerals. With the right solution, these abundant and local resources can become strategic, high-efficiency feedstocks — right where they are needed most.

At the same time, lithium demand is accelerating. Battery makers are searching for secure, scalable, and sustainable supply. And oil & gas producers, midstream companies, and geothermal operators are managing brines rich in lithium — currently treated as a byproduct.

The opportunity? Turn that byproduct into a revenue-generating resource while enhancing ESG performance, bolstering energy security, and establishing a resilient, domestic supply chain.

Why rely on distant, high-cost sources when the solution is already below your feet? With Lithium Harvest, you are not just adapting to the new energy economy — you are leading it.

Revolutionary Lithium Extraction Technology

Unlocking the value of lithium-rich brines with sustainable extraction technologies.

At Lithium Harvest, we have developed a patented, field-proven solution that transforms lithium-rich brines, including oilfield wastewater and geothermal brine, into high-purity, battery-grade lithium compounds.

By combining advanced Direct Lithium Extraction (DLE) with decades of water treatment expertise, our solution transforms what was once a costly byproduct into a scalable, sustainable, revenue-generating multi-use resource. By recovering lithium and other critical minerals, our solution addresses two major challenges: sustainable resource recovery and responsible water management. Every water source is unique, and our team of experts with years of experience in industrial wastewater treatment has developed a solution that adapts to these variations, ensuring the highest lithium recovery rates with safe, efficient production.

We do not just extract lithium. We build complete solutions designed for real-world operations.

Our solution is:

- Designed for Co-Location – Integrated directly into existing midstream and geothermal infrastructure, reducing CapEx and permitting requirements.

- Built to Extract & Refine at the Source – Eliminates the need for off-site refining and long-haul transport.

- Modular & Scalable – Compact footprint, plug-and-play design, and flexible sizing to match your production volumes.

- Environmentally Responsible – Uses less land, less energy, and recycles over 90% of the water used.

Whether you are managing produced water, geothermal brines, or other lithium-bearing fluids, we provide a turnkey path to turn your byproduct into profit — and meet rising ESG expectations along the way.

This is more than a clean tech upgrade. It is a new revenue stream, a sustainability advantage, and a competitive edge.

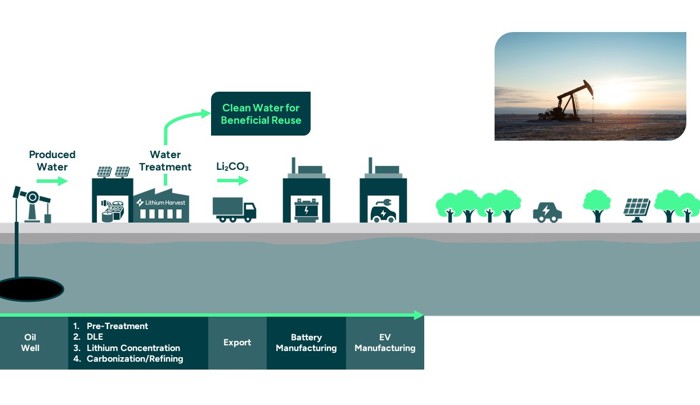

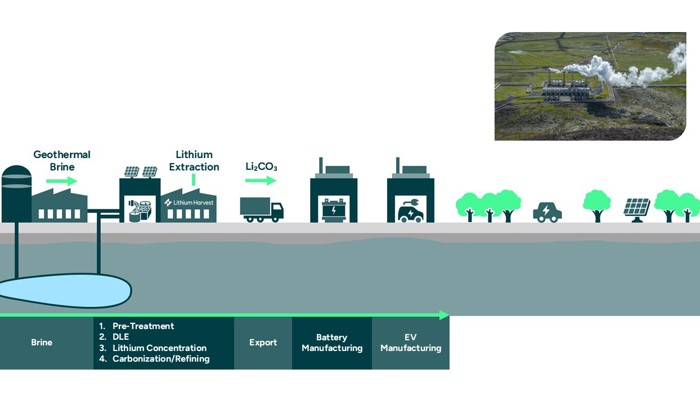

From Waste to Value: Extracting Valuable Resources

Revolutionizing resource management – Lithium Harvest's patented Direct Lithium Extraction (DLE) technology and advanced water treatment transform a once costly byproduct into a valuable, multi-use resource.

We utilize our proprietary DLE technology in synergy with advanced water treatment to unlock the hidden potential of produced water — a byproduct of oil and gas operations — as well as geothermal brines and other lithium-rich sources. We have embedded decades of water treatment expertise into the process — reducing scaling, improving uptime, and boosting extraction performance.

By combining these cutting-edge approaches, we are redefining brine management, turning what was once considered waste into a strategic asset with far-reaching environmental and economic benefits.

Our five-step process ensures efficient resource extraction and repurposing:

- Collection: Produced water, geothermal brines, and other brine sources are collected directly from wells, midstream companies, or geothermal operations, laying the foundation for their transformation.

- Filtration & Separation: Advanced filtration and separation remove solids, hydrocarbons, heavy metals, and other contaminants, ensuring the water is ready for further treatment.

- Advanced Water Treatment: Using innovative, proven technologies, the purified water undergoes further treatment to meet stringent quality standards for resource extraction and production efficiency.

- Resource Extraction: Our process extracts critical minerals, including lithium, from treated water and brines, turning waste into a valuable resource while supporting the transition to green energy.

- Repurposing: Once treated and free from contaminants, the water can be repurposed for various sustainable uses, such as freshwater supply, industrial or agricultural applications, reservoir reinjection, or innovative sustainability-focused projects.

A comprehensive, future-ready process that transforms lithium-rich brines into dual assets — supporting both economic growth and environmental responsibility. Lithium Harvest is leading the charge in transforming brine into value while helping our partners meet their ESG goals and unlock new revenue streams.

The Journey of Sustainable Lithium

Direct Lithium Extraction - But Different

Lithium Harvest's proprietary Direct Lithium Extraction (DLE) technology utilizes state-of-the-art adsorption technology combined with advanced water treatment to revolutionize lithium production by leveraging oil and gas wastewater as feedstock, as well as other lithium-bearing brine sources. Experience the pinnacle of innovation with Lithium Harvest, offering the market's fastest and most cost-effective lithium mining technology. Our process sets the global standard for sustainability in lithium extraction.

Lithium Harvest Solution |

DLE from Brine |

Lithium Harvest Advantage |

|

|---|---|---|---|

| Feedstock | Produced water/geothermal brine | Continental brine | No drilling permits needed |

| Project implementation time | 12-15 months | 5-7 years | No asset acquisition |

| System design | Modular and mobile | Mobile / stationary | Unique modular design |

| Water consumption | 20 million gallons | 80 million gallons | Water recycled for secondary reuse |

| CO₂ footprint | Neutral | 1.5 million kg | Offsets CO₂ footprint from wastewater |

| Average invested capital per 1,000 mt LCE | $18 million | $45 million | No land acquisition |

| Average cost per metric ton | $4,550 | $5,700 | Low energy technology |

Lithium Harvest Solution

DLE from Brine

Lithium Harvest Advantage

Technological Benchmark

Our innovation surges ahead of our competitors.

Lithium Harvest Solution |

DLE from Brine |

Solar Evaporation Brine Extraction |

Hard Rock Mining |

|

|---|---|---|---|---|

| Feedstock | Produced water/geothermal brine | Continental brine | Continental brine | Rock / spodumene |

| Project implementation time | 12-15 months | 5-7 years | 13-15 years | 8-10 years |

| Lithium carbonate production time | 2 hours | 2 hours | 2-3 years | 3-6 months |

| Lithium yield | >95% | 80-95% | 20-40% | 6-7% |

| Average footprint per 1,000 mt LCE | 1.4 acres | 1.4 acres | 65 acres | 115 acres |

| System design | Modular and mobile | Mobile / stationary | Stationary | Stationary |

| Environmental impact | Minimal | Minimal | Soil- and water contamination | Soil- and water contamination |

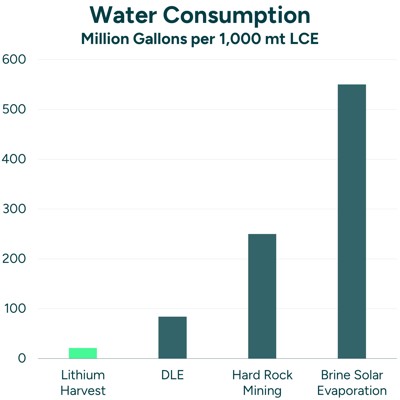

| Water consumption per 1,000 mt LCE | 20 million gallons | 80 million gallons | 550 million gallons | 250 million gallons |

| CO₂ footprint per 1,000 mt LCE | Neutral | 1.5 million kg | 5 million kg | 15 million kg |

Lithium Harvest Solution

DLE from Brine

Solar Evaporation Brine Extraction

Hard Rock Mining

Where Green Technology Drives Business Forward

Our innovative approach at Lithium Harvest sets a new standard in the lithium industry, surpassing traditional methods like DLE, hard rock mining, and brine solar evaporation.

Eco-Friendly Operations: Our low-pressure and energy-efficient technology leverages solar power, significantly reducing carbon emissions. With no need for transportation to secondary sites and offsetting carbon savings from water handling, we maintain a low environmental impact.

Compact Facility Design: Strategically co-located with water treatment facilities, our compact, modular design minimizes land use and protects natural habitats, eliminating the need for ponds or pipelines.

Water Conservation Leader: We champion sustainability by recycling over 90% of the water used, ensuring that no freshwater is consumed or polluted, and producing no additional waste.

Cost Efficiency: Our on-site low-energy process reduces CapEx and OpEx. No land or drilling rights purchases, fixed-price feedstock, and a high-yield, automated facility translate into lower costs per ton of lithium.

Speedy Implementation: No need for land acquisition and drilling permits, and with a modular and scalable plant design that enables quick project rollouts and swift adaptation to market needs.

Lithium Harvest is not just about extracting lithium; it is about setting new benchmarks for sustainability and efficiency in the industry.

Lithium Harvest vs. Traditional Lithium Mining

Fun Fact (That is Also a Little Alarming)

Did you know that traditional lithium mining methods are incredibly resource-intensive? They can consume millions of gallons of water — enough to fill hundreds of Olympic-sized swimming pools — and release vast amounts of CO₂ into the atmosphere.

At Lithium Harvest, we do things differently. By utilizing produced water and geothermal brine as our feedstock, we help meet global lithium demand while significantly reducing the environmental impact.

Here is the difference we make with every 1,000 metric tons of lithium carbonate produced:

- Up to 15 million kg of CO₂ emissions saved

– That is like taking over 3,200 cars off the road for an entire year - 500 million gallons of water conserved

– Enough to fill 750+ Olympic-sized swimming pools

– Or meet the annual water needs of 4,500 U.S. households - No evaporation ponds. No land disruption. No freshwater use.

– Our process runs in a closed loop with over 90% water recycled

And we are just getting started. The world will need millions of tons of lithium in the coming decades. That is a lot of water, carbon, and waste saved — or not. Something to think about.

Instead of generating new waste, we turn waste into value — producing battery-grade lithium from what was once a costly disposal problem.

Every drop counts. Every ton makes a difference.

One Technology. Multiple Industries. Maximum Impact.

Our technology is not one-size-fits-all — it is engineered to integrate with your existing operations, regardless of where you sit in the energy or battery value chain. Whether you manage produced water, operate a geothermal plant or secure battery materials; Lithium Harvest helps you unlock new value quickly.

A Win-Win Solution Across Industries

Real value for every stakeholder in the energy transition.

Lithium Harvest bridges the gap between legacy energy systems and the future of clean technology. Our solution delivers real commercial and environmental value across the energy and battery supply chain, enabling oil and gas producers, geothermal operators, and battery manufacturers to work together in a smarter, more sustainable way.

-

For the Oil & Gas Industry

Unlock Hidden Value in Produced Water

- Extract critical minerals from a costly waste stream

- Reduce disposal volumes and associated costs

- Repurpose treated water for industrial or reinjection uses

- Improve ESG performance and stakeholder trust

- Seamlessly integrate into SWD and midstream infrastructure

-

For Geothermal Operators

Enhance Brine Value Without Disrupting Power Output

- Extract lithium alongside energy production

- Co-locate with existing geothermal facilities

- Create a new revenue stream without expanding footprint

- Boost ROI on geothermal assets and improve sustainability profile

-

For the Lithium & Battery Supply Chain

A Faster, Cleaner, More Secure Supply of High-Quality Lithium

- Battery-grade lithium compounds with exceptional purity and consistency

- One of the most sustainable extraction methods in the world

- Up to 47% lower lifecycle emissions for batteries

- Domestic supply with faster time-to-market

- Competitive pricing with flexible, scalable production

We Design. We Build. We Operate. You Profit.

Elevating lithium extraction: Expertise that drives innovation and joint growth.

At Lithium Harvest, we are more than just a technology provider — we are a full-scale lithium extraction company and a long-term partner in sustainable lithium extraction. Our turnkey approach eliminates the complexity and capital requirements for you. With decades of experience in industrial water treatment engineering and process design, we do not just deliver equipment — we deliver outcomes.

Through our DBOO model — Design, Build, Own, Operate — we develop and operate lithium extraction plants directly on-site, allowing you to unlock value from your brine with low risk and high reward.

Proven, Scalable, and Ready to Go

We are already working with industry leaders — including partners producing over 70,000 tons of lithium carbonate annually — proving that our technology and operating model are ready to scale now.

We offer tailored business scenarios that foster joint growth, ensuring every partnership is built for shared success and long-term value creation.

Ready to turn brine into a business advantage?

Let’s explore how Lithium Harvest can help you unlock new revenue, enhance ESG performance, and drive the clean energy future — directly from your existing operations.

Contact Us

Our team of water treatment and extraction experts is ready to help you.