Critical Raw Materials

For a sustainable future - navigating the surge in demand for critical raw materials.

Introduction - The Pivotal Role of Critical Raw Materials in Shaping Our Future

In a world where technological progress and environmental responsibility are top priorities, Critical Raw Materials (CRMs) have become essential to building a sustainable future.

CRMs include a wide range of metals, minerals, and natural elements that serve as the backbone of modern industries. What makes them "critical" isn't just their economic value - it's the high risk of supply disruption. Ensuring access to these materials is now a top strategic priority for governments and industries worldwide.

CRMs' role extends far beyond traditional manufacturing. They are central to the green energy transition, supporting everything from solar panels and wind turbines to electric vehicles and energy storage. Lithium, for example, is a key ingredient in the batteries powering EVs, grid storage systems, and countless consumer technologies. As we shift toward electrification and decarbonization, the demand for lithium and other CRMs is rising sharply.

This rising demand highlights a bigger responsibility: securing CRMs in a sustainable way. It's not just about finding more - it's about extracting and using them in ways that respect the environment, preserve natural resources, and create long-term resilience.

The story of CRMs is no longer just about supply and demand. It's about environmental stewardship, innovation, and building a circular economy that supports future generations. At Lithium Harvest, we're proud to be part of that movement - delivering cleaner, more efficient ways to recover critical minerals and support the global energy transition.

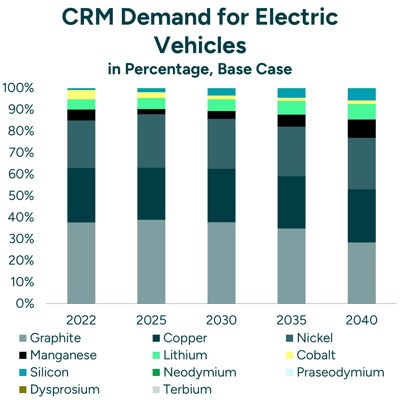

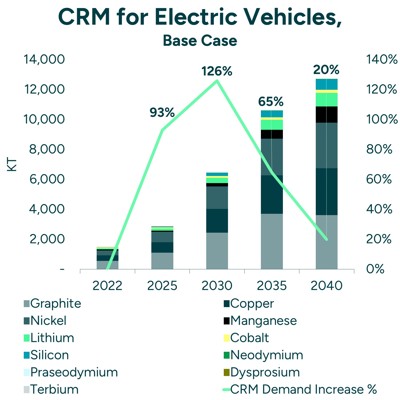

The surge in electric vehicles is accelerating global demand for critical raw materials, and the numbers are striking. Between 2022 and 2040, CRM demand is set to skyrocket, with a projected increase of over 126% between 2025 and 2030. In fact, by 2025 alone, we're already seeing a staggering 93% jump.

This dramatic growth is a clear signal. The world is moving fast toward cleaner, electrified transportation and away from fossil fuels. But with this transition comes a significant challenge – how to secure the raw materials needed without creating new environmental problems.

Meeting this rising demand will require more than traditional mining. It will require smarter strategies, such as sustainable extraction, advanced recycling, and better material efficiency. These approaches are not just helpful - they're essential for keeping pace with demand while protecting the planet.

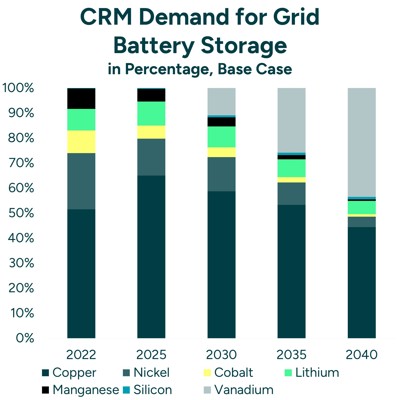

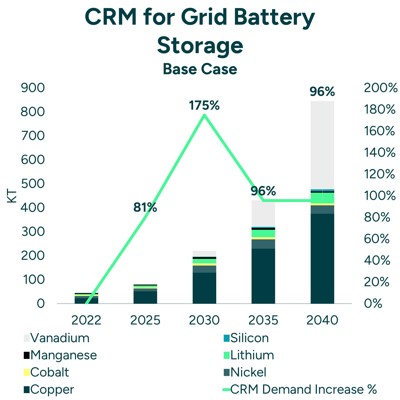

Demand for critical raw materials used in grid energy storage is set to explode between 2022 and 2030. From 2022 to 2025, we expect an 81% increase. Then, it accelerates even further,, with a projected 175% rise from 2025 to 2030.

This surge reflects a bigger shift. As more solar and wind power comes online, grid storage is becoming essential. These systems keep electricity flowing even when the sun isn't shining or the wind isn't blowing, making them the backbone of a resilient, low-carbon energy grid.

But rapid growth comes with responsibility. To support this transition, we need more innovative, more sustainable ways to extract and recycle the materials that make storage possible. That means innovating beyond traditional mining and embracing circular solutions that reduce waste and environmental impact.

The European Critical Raw Materials Act - Securing Supply for a Sustainable Future

The European Critical Raw Materials Act (CRMA) is a game-changing initiative aimed at strengthening the European Union's resilience and reducing its dependence on imports of essential raw materials from third countries. Critical and strategic raw materials are at the heart of the green and digital transitions and vital to the defense and space sectors. The CRMA lays out a comprehensive roadmap for long-term supply chain security.

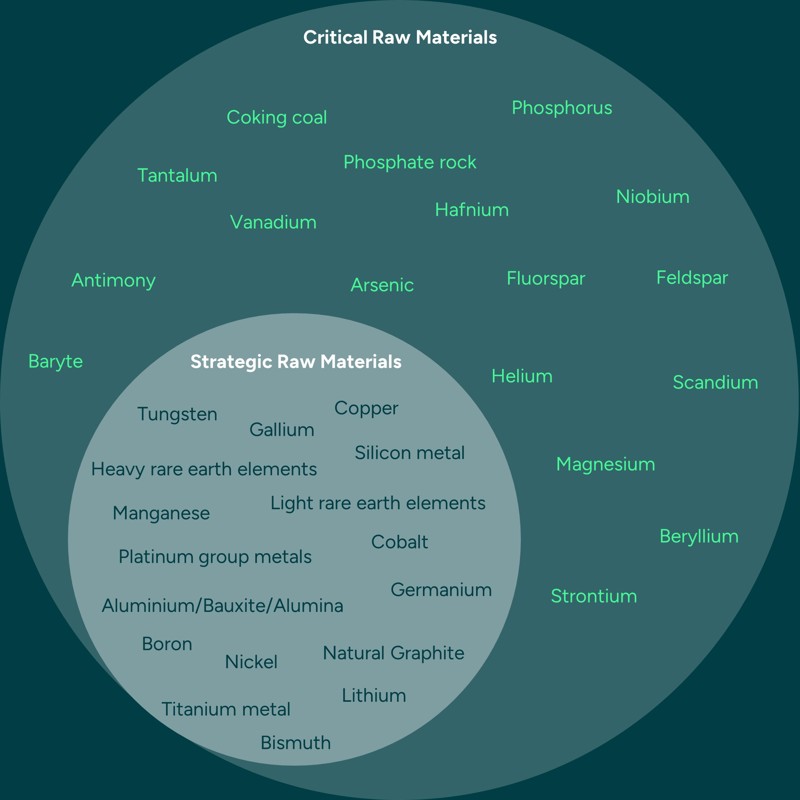

Two lists, one clear mission

At the core of the CRMA are two carefully curated lists:

-

34 Critical Raw Materials (CRM)

-

17 Strategic Raw Materials (SRM) – selected based on projected exponential demand growth and complex, high-risk production processes.

These lists serve a dual purpose: prioritizing the materials most essential to Europe's transition and ensuring their availability across key industries.

Ambitious benchmarks to build self-sufficiency

To reduce reliance on single-source imports and bolster internal supply chains, the CRMA sets clear targets for the EU's annual consumption of raw materials:

-

At least 10% from local extraction

-

At least 40% processed within the EU

-

At least 25% from recycled sources

-

No more than 65% of any SRM at any stage should come from a single non-EU country

These benchmarks aim to balance local sourcing, sustainable processing, and the principles of the circular economy.

Faster project approvals, less red tape

To speed up development, the CRMA requires EU member states to establish single points of contact for strategic projects. These designated authorities will support implementation at every stage of the value chain, removing bureaucratic delays and enabling faster action where it is needed most.

A strategic vision for Europe

The CRMA is more than a policy - it's a blueprint for a future where Europe leads in sustainable resource management. It encourages investment in innovative extraction and recycling technologies and calls on industry and governments to collaborate to strengthen Europe's independence, competitiveness, and climate goals.

EU Critical Raw Materials |

|

|---|---|

| Critical Raw Materials | Coking Coal, Phosphorus, Antimony, Feldspar, Scandium, Arsenic, Fluorspar, Magnesium, Baryte, Strontium, Beryllium, Tantalum, Hafnium, Niobium, Helium, Phosphate Rock, and Vanadium. |

| Strategic Raw Materials | Aluminium/Bauxite/alumina, Lithium, Light rare earth elements, Silicon metal, Gallium, Manganese, Germanium, Natural Graphite, Bismuth, Titanium metal, Boron, Platinum group metals, Tungsten, Cobalt, Heavy rare earth elements, Copper, and Nickel. |

EU Critical Raw Materials

The U.S. Approach to Critical Materials - Policy, Security, and Sustainability

In the United States, securing the supply and supporting the sustainable development of Critical Materials and Minerals is a national priority. The country's approach is multifaceted and reflects strategic interests in economic resilience, technological leadership, and environmental sustainability. Key policies and legislative actions, including initiatives from the Department of Energy (DOE) and the Inflation Reduction Act, form the foundation of this strategy.

What makes a material 'critical'?

The DOE defines Critical Materials and Critical Minerals as those essential to important technologies, but at risk of supply disruption. These materials are crucial for renewable energy, defense systems, advanced electronics, and electric vehicles. Their availability affects everything from economic competitiveness to national security, which is why securing them is so important.

The role of the Inflation Reduction Act

While the Inflation Reduction Act is known for its focus on climate and economics, it also directly impacts critical material supply chains. The Act encourages investment in clean energy, electric vehicles, and batteries, all of which rely heavily on Critical Materials. The incentives are designed to build domestic capabilities and reduce dependence on imports from less stable regions.

It also promotes research and innovation to develop cleaner, more efficient ways of extracting and recycling these materials. This includes support for new technologies that reduce environmental harm and lower processing costs.

Strengthening U.S. production and circularity

The Act supports U.S.-based production and prioritizes sustainability. It encourages companies to recycle materials, minimize waste, and build economically and environmentally sound supply chains. By developing critical minerals domestically, the U.S. reduces vulnerability to global supply chain disruptions and improves self-sufficiency.

A strategic alignment for a sustainable future

The combined approach - pairing the DOE's strategic planning with the Inflation Reduction Act's financial incentives - positions the U.S. to lead in the development of critical minerals. This strategy strengthens national supply chains and aligns with global calls for responsible and sustainable resource management.

In short, the U.S. isn't just preparing for the clean energy transition - it's building the foundation to lead it.

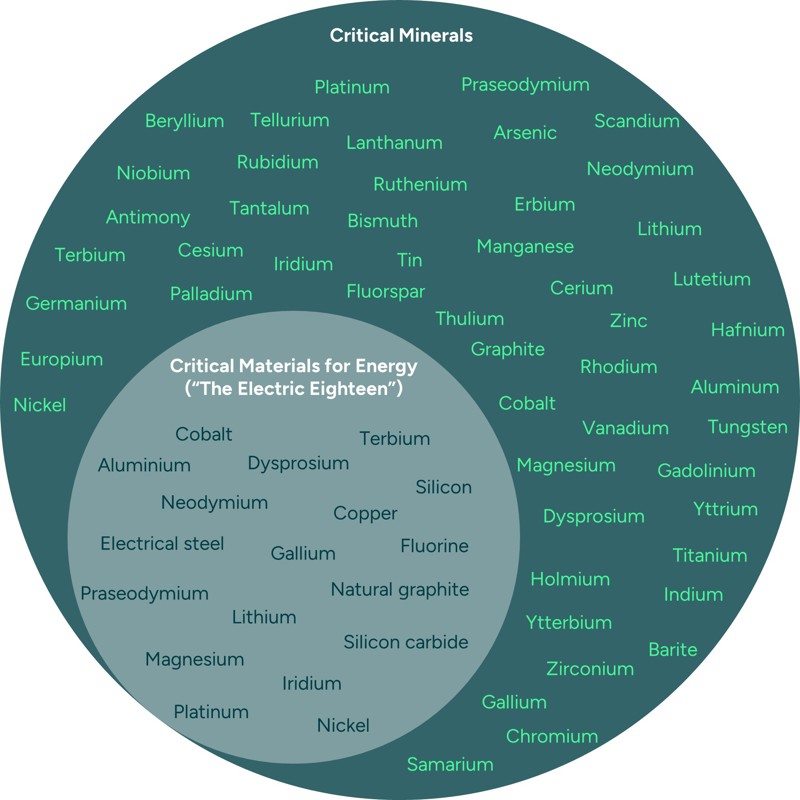

US Critical Raw Materials |

|

|---|---|

| Critical Materials for Energy (“the electric eighteen”) | Aluminum, Cobalt, Copper, Dysprosium, Electrical steel, Fluorine, Gallium, Iridium, Lithium, Magnesium, Natural graphite, Neodymium, Nickel, Platinum, Praseodymium, Silicon, Silicon carbide, and Terbium. |

| Critical Minerals | Aluminum, Antimony, Arsenic, Barite, Beryllium, Bismuth, Cerium, Cesium, Chromium, Cobalt, Dysprosium, Erbium, Europium, Fluorspar, Gadolinium, Gallium, Germanium, Graphite, Hafnium, Holmium, Indium, Iridium, Lanthanum, Lithium, Lutetium, Magnesium, Manganese, Neodymium, Nickel, Niobium, Palladium, Platinum, Praseodymium, Rhodium, Rubidium, Ruthenium, Samarium, Scandium, Tantalum, Tellurium, Terbium, Thulium, Tin, Titanium, Tungsten, Vanadium, Ytterbium, Yttrium, Zinc, and Zirconium. |

US Critical Raw Materials

The Importance of Lithium as a Critical Raw Material

Lithium, a pivotal element on the Critical Raw Materials (CRM) list, has become a cornerstone of modern technology and global sustainability efforts. Thanks to its high energy density and lightweight properties, it's essential for powering the batteries that drive electric vehicles (EVs) and store renewable energy.

But lithium's significance goes far beyond technical performance. As the world shifts toward greener technologies and electrified transportation, lithium has taken center stage as a strategic resource. It enables the large-scale integration of renewable energy sources, like wind and solar, into power grids and helps reduce our reliance on fossil fuels.

In the U.S., lithium is classified as one of the "electric eighteen" - critical materials vital to future energy systems. The European Union has also recognized lithium as a Strategic Raw Material (SRM), anticipating exponential growth in demand as the green transition accelerates.

Demand for lithium is already surging. Driven by the rapid adoption of electric vehicles (EVs) and the expansion of clean energy infrastructure, global demand for lithium is expected to rise dramatically over the next decade. This presents both massive opportunities and pressing challenges. On one hand, it reinforces lithium's critical role in enabling a sustainable energy future. On the other hand, it highlights the urgent need for more responsible, scalable, and efficient ways to extract and process it.

A secure, sustainable lithium supply chain is about more than meeting demand - it's about reducing environmental impact, ensuring ethical sourcing, and supporting the global push for decarbonization.

Lithium is more than a commodity. It's a key enabler of the renewable energy revolution and a critical building block in our shared path toward a cleaner, more electrified future.

Navigating the Complex Terrain of CRM Extraction - Environmental and Ethical Challenges

Extracting Critical Raw Materials (CRMs) isn’t just a technical process - it’s a complex issue related to some of the most pressing environmental and ethical challenges of our time.

Demand for CRMs is soaring, as they power everything from clean energy to advanced electronics. However, traditional extraction methods often have serious consequences, including land degradation, excessive water use, and social disruption in communities near mining sites.

That’s why sustainable and responsible mining practices are more than a nice-to-have - they’re essential. The industry must evolve by adopting cleaner technologies, reducing energy and water consumption, and committing to fair, transparent operations that respect local communities and Indigenous rights.

This also means restoring ecosystems after mining ends and designing operations that protect both people and the planet from the start. With more innovative approaches, the mining sector can play a key role in delivering the materials we need without repeating the mistakes of the past.

-

The carbon footprint of CRM extraction

Extracting and processing Critical Raw Materials (CRMs) often comes with a heavy carbon cost. From powering heavy machinery to burning fossil fuels during extraction and shipping materials across the globe, every step in the process contributes to greenhouse gas emissions.

These emissions increase operational costs and accelerate climate change, adding to the pressure on an already warming planet. Reducing the carbon footprint of CRM extraction is no longer just a climate issue - it’s central to aligning the mining sector with global sustainability goals.

To meet growing demand without worsening environmental damage, the sector needs cleaner energy sources, more innovative logistics, and more efficient processes that minimize emissions from the ground up.

-

The water footprint of mining

Mining operations rely heavily on water, not just for extracting materials, but also for processing and dust control. This high demand can place severe strain on local water supplies, especially in already arid regions. It’s not just about volume, either.

The risk of water pollution from mining runoff is a genuine concern. When mining effluents enter nearby rivers or groundwater, they can degrade water quality, harm aquatic ecosystems, and even pose risks to human health. For nearby communities and farmers, it means less clean water for drinking, irrigation, and daily life.

As demand for Critical Raw Materials continues to rise, sustainable water management must be part of the solution.

-

Land disruption and biodiversity loss

Traditional mining of Critical Raw Materials (CRMs) often comes at a steep environmental cost. Open-pit mines, in particular, leave massive scars on the landscape, displacing wildlife, disrupting ecosystems, and wiping out natural habitats.

These operations can also degrade soil and cause long-term damage to the surrounding environment. Mining waste, if not properly managed, can leach into nearby soil and water, contaminating both and creating hazards that last well beyond the mine's life.

As the demand for CRMs grows, so does the responsibility to protect the environments in which we mine. Minimizing land impact and preserving biodiversity must be part of a modern, responsible mining strategy.

-

Social impacts on local communities

Extracting Critical Raw Materials (CRMs) is not just an environmental issue - it also has profound social implications. In many regions, mining operations have displaced communities, lost traditional livelihoods, and violated Indigenous rights.

Local populations often bear the brunt of large-scale extraction projects without reaping the benefits. This imbalance creates social tension and, if not addressed responsibly, can lead to long-term harm.

Sustainable CRM development must go beyond resource extraction. It should prioritize fair treatment, community engagement, and respect for cultural and territorial rights, ensuring that progress does not cost the people closest to it.

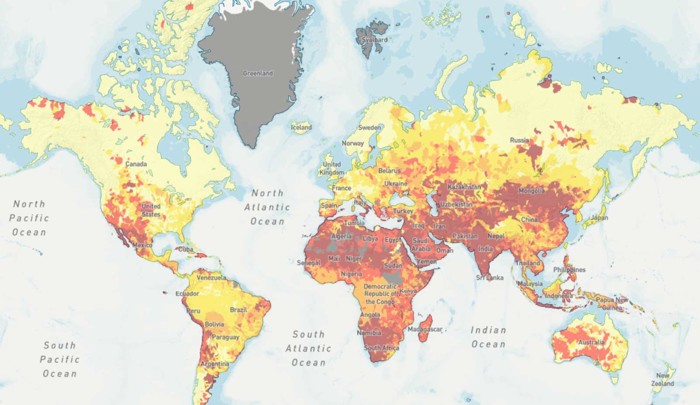

The Water Stress Challenge in Critical Mineral Extraction

Water is one of the most pressing - and often overlooked - challenges in the race for critical raw materials. According to the World Resources Institute (WRI), mining operations for essential minerals like lithium are incredibly water-intensive, especially in arid regions. These projects use huge volumes of water to process materials, control dust, and keep operations running. The result? Strained local supplies, rising competition with communities and agriculture, and greater risks of water pollution.

A closer look at data from the U.S. Geological Survey (USGS) and the World Resources Institute's (WRI) Aqueduct Water Risk Atlas sheds light on the significant water challenges associated with critical mineral mines:

- 16% of global critical mineral mines are in areas with high or extremely high water stress - places where more than 40% of available water is already in use.

- 8% are in low-water or arid zones where even modest mining expansion could tip the balance toward crisis.

- And by 2050, the share of critical mineral locations in high-stress water zones is expected to rise to 20%.

The message is clear: as we scale up clean energy, we can't ignore water. A sustainable energy future must include more innovative and efficient water use.

Lithium Harvest's answer to the water problem

At Lithium Harvest, we know there's a better way. Our patented technology extracts lithium from oil and gas wastewater, reducing the need for fresh water and minimizing environmental impact.

- We save up to 500,000 gallons of freshwater per metric ton of lithium carbonate produced.

- We recycle over 90% of the water used in our process.

- And we help oil and gas companies turn a costly waste stream into a valuable resource.

By reducing freshwater use and repurposing industrial byproducts, we're proving that sustainability and profitability can coexist. It's not just possible - it's happening.

Fostering Sustainability Across CRM Supply Chains - A Vision for the Future

Building sustainability into Critical Raw Material supply chains

The need for sustainability across Critical Raw Material (CRM) supply chains is more urgent than ever. As CRMs power everything from electric vehicles to renewable energy storage and advanced technologies, the challenge is clear: meet rising demand while reducing environmental impact and upholding ethical standards.

From ground to product: Where sustainability starts

A sustainable CRM supply chain begins at the source - but it doesn’t stop there. From extraction and refining to manufacturing and final use, every stage is an opportunity to operate more responsibly. This includes:

- Minimizing land and water use

- Lowering carbon emissions

- Promoting fair labor practices

- Engaging with local communities

Sustainability shouldn’t be a side effort - it should be embedded in every part of the process, driving long-term efficiency and accountability.

Lithium Harvest: Leading by example

At Lithium Harvest, we’re showing what sustainable extraction can look like in action. Our proprietary technology extracts lithium and other critical minerals from oilfield wastewater, turning an environmental burden into a high-value resource.

Here’s what makes our model different:

- No need for evaporation ponds or open-pit mines

- Up to 90% of water is reused

- Carbon emissions are significantly reduced

- Existing oil and gas infrastructure is repurposed, avoiding new land disruption

We’re not just minimizing impact - we’re redefining what responsible lithium extraction should be. By transforming waste into value and lowering our footprint, we’re setting a new benchmark for the CRM industry.

Energy Transition

You may also be interested in: