Environmental Impact of Lithium Extraction From Produced Water

Explore the environmental impacts and potential of lithium extraction from produced water.

Introduction

As global demand for lithium continues to surge, driven by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems, the need for more sustainable extraction methods has never been greater. Traditional mining techniques are often environmentally damaging, depleting water resources, disrupting ecosystems, and contributing to greenhouse gas emissions.

But what if there were a way to turn a problem into a solution? The oil and gas industry faces a significant challenge with produced water, a byproduct of oil and gas extraction that often requires costly disposal. What if this waste stream could be transformed into a valuable resource instead of a liability?

Lithium Harvest’s lithium extraction solution offers a revolutionary way to do just that. By integrating Direct Lithium Extraction (DLE) technology with advanced water treatment processes, we provide a cleaner, greener, and more profitable future for the oil and gas industry.

Table of contents:

- The Environmental Challenges of Traditional Lithium Extraction

- The Potential of Lithium Extraction from Produced Water

- Environmental Impacts of DLE From Produced Water

- Leading the Charge with Environmental-Friendly Extraction From Produced Water

- Surge Ahead With DLE From Produced Water

- Innovative Solution for DLE From Produced Water

- Future Outlook - Pioneering a Greener, More Sustainable Future

The Environmental Challenges of Traditional Lithium Extraction

Lithium is critical to the transition to a low-carbon economy. However, conventional extraction methods, such as open-pit mining and evaporation ponds, have serious environmental consequences.

Open-pit mining:

- Causes extensive land disruption, habitat destruction, and soil erosion

- Generates hazardous waste that can contaminate air, soil, and water

Evaporation ponds:

- Use massive amounts of water, especially in already dry regions

- Deplete local water sources, impacting nearby communities and ecosystems

- Raise serious concerns about water availability and long-term sustainability

These drawbacks make one thing clear: we need better solutions. As the world races toward electrification, continuing with traditional mining methods just isn’t practical - or responsible.

So, the big question is: How can we extract lithium in a way that promotes environmental stewardship and profitability?

The Potential of Lithium Extraction from Produced Water

What if your industry's waste could be transformed into a valuable, revenue-generating asset?

Produced water - a byproduct of oil and gas extraction - is often viewed as a costly nuisance, requiring extensive treatment and disposal. But what if that same water held the key to unlocking one of the world's most critical resources: lithium?

A paradigm shift in resource utilization

Produced water is typically considered a waste stream. It contains salts, hydrocarbons, heavy metals, and other impurities that make disposal both challenging and expensive. But it also contains valuable minerals, notably lithium, essential for manufacturing EV batteries and renewable energy storage systems.

At Lithium Harvest, we've pioneered a solution that turns this overlooked resource into a powerful revenue stream. By integrating Direct Lithium Extraction (DLE) with advanced water treatment technologies, we help oil and gas companies convert their produced water from a disposal problem into a profitable asset.

Environmental and economic benefits

By embracing this approach, oil and gas operators can achieve multiple goals:

- Reduce environmental impact: Unlike traditional lithium mining, which disrupts ecosystems and consumes massive amounts of water, extracting lithium from produced water has a much smaller environmental footprint.

- Generate new revenue streams: Turning waste into value isn't just good for the environment - it's a smart business move. Monetizing produced water boosts profitability while supporting the green energy transition.

- Improve water management: Instead of simply disposing of produced water, this solution treats, recycles, and repurposes it, reducing disposal costs and supporting responsible water stewardship.

- Monetize resources: By eliminating waste, you're creating a new revenue stream from something previously discarded.

- Boost ESG performance: Integrating DLE helps demonstrate your commitment to sustainability by turning a waste stream into a cleaner, profitable process.

- Maximize operational synergy: Our system integrates directly into your existing produced water treatment infrastructure, so you get a streamlined, low-disruption path to innovation.

Bottom line: Lithium extraction from produced water isn't just about compliance - it's about unlocking new value, boosting operational efficiency, and building stronger environmental credibility.

Environmental Impacts of DLE From Produced Water

Lithium extraction from produced water offers transformative environmental benefits compared to traditional methods. Instead of disrupting ecosystems or consuming massive amounts of freshwater, this innovative approach taps into a waste stream, creating new opportunities for the oil and gas industry to boost profitability while significantly reducing environmental impact.

-

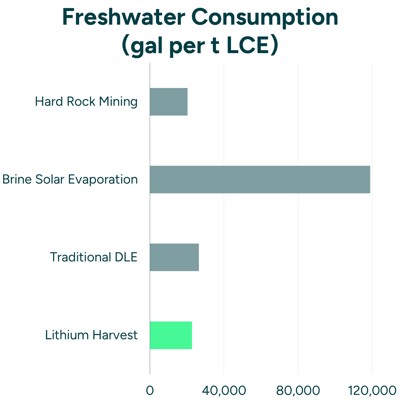

Water conservation and recycling

Traditional mining methods and evaporation ponds are notorious for their excessive water consumption. On the other hand, our process drastically reduces water usage by extracting lithium directly from produced water, a resource already generated by oil and gas operations.

Our system is designed to recycle over 90% of water, highlighting our commitment to responsible water management. This efficient recycling eases pressure on local freshwater supplies and reduces the environmental risks of produced water disposal.

A real-world example: For every ton of lithium carbonate we produce, our process can save up to 118,877 gallons of freshwater - and at 1,000 tpa that’s ~119 million gallons a year, roughly 1,000 U.S. households or ~450,000 m³ (~180 Olympic pools). This breakthrough in efficiency represents up to a 81% reduction in water consumption compared to conventional mining.

By reusing produced water, oil and gas companies can turn a costly waste stream into an environmental asset - and prove their commitment to sustainable water stewardship.

-

Resource optimization and waste minimization

Produced water is often seen as a costly byproduct of oil and gas extraction. But our technology makes it entirely different - a valuable resource. We’re extracting lithium and other critical minerals from it, turning what was once a waste stream into a new source of revenue. And thanks to our advanced water treatment technology, that same water can be reused for irrigation, freshwater production, or reinjection.

What’s more, our process integrates seamlessly with existing produced water treatment facilities. That means no major infrastructure overhauls and minimal operational disruption. It’s a practical, low-barrier solution for oil and gas companies looking to boost profitability while advancing their sustainability commitments.

-

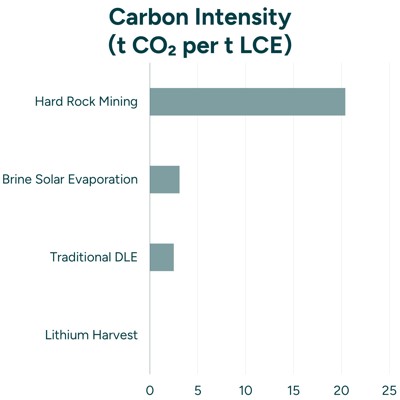

Reduced carbon footprint

The energy-intensive nature of conventional lithium mining and processing leads to significant greenhouse gas emissions. In contrast, extracting lithium from produced water is a cleaner, more energy-efficient alternative.

Our solution is designed to run with minimal energy input, and wherever possible, we power our operations using renewable sources like solar. The result? A carbon-neutral process that dramatically reduces greenhouse gas emissions per metric ton of lithium produced.

This lower carbon footprint helps drive global climate goals forward while also supporting the oil and gas industry's role in the energy transition.

-

Ecosystem preservation

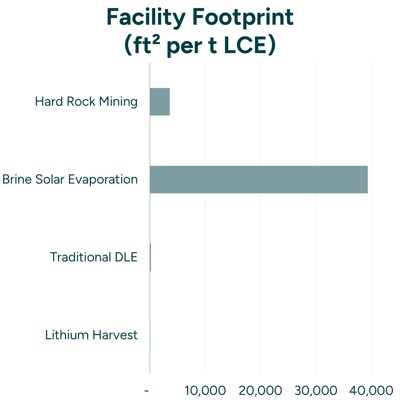

Conventional lithium extraction methods, such as open-pit mining and evaporation ponds, often lead to land degradation, habitat destruction, and soil erosion. Lithium extraction from produced water avoids all of these problems.

Our modular, compact facility design keeps land use to a minimum, helping protect local ecosystems and wildlife. By extracting lithium without disturbing the environment, we're making a meaningful step forward in responsible resource management.

Leading the Charge with Environmental-Friendly Extraction From Produced Water

Lithium Harvest's approach to lithium extraction from produced water marks a significant step forward in sustainable resource recovery. We're not just producing lithium - we're transforming how it's sourced, turning an environmental challenge into a powerful, profit-generating opportunity for the oil and gas industry.

Efficient and eco-conscious extraction

We understand the complexities of oil and gas operations and have built our solution to integrate with your existing infrastructure seamlessly. By co-locating our facilities at produced water treatment sites, we eliminate the need for long-distance transport, cutting costs and carbon emissions.

Our process is designed to be:

- Energy-efficient: We prioritize renewable energy sources like solar power to keep our CO₂ footprint neutral and aligned with global climate goals.

- Low-pressure operation reduces energy use and optimizes water management for better sustainability.

- Operationally compatible: Our system integrates directly into produced water treatment facilities, making deployment fast, simple, and non-disruptive.

Compact, modular facility design

Land use and ecological impact matter, especially in sensitive oil and gas zones. That's why we developed a modular, compact facility design that fits neatly alongside your operations. Unlike traditional lithium extraction, which requires large mines and evaporation ponds, our solution keeps the footprint small while delivering significant results. The benefit? Preserved ecosystems and protected local wildlife.

Revolutionary water management

Water is one of the oil and gas industry's most precious and challenging resources. With Lithium Harvest's solution, over 90% of water is recycled in the extraction process. This turns a waste stream into a sustainable resource, minimizing reliance on local freshwater and drastically reducing disposal needs.

Our closed-loop system doesn't generate harmful byproducts, proving our commitment to responsible water stewardship and long-term environmental integrity.

Setting a new standard in sustainability

Choosing Lithium Harvest isn't just good business - it's a bold step toward a more sustainable future. Here's what you gain:

- A stronger ESG profile backed by responsible water management and carbon-neutral operations.

- Seamless integration with your existing facilities for faster deployment and minimal disruption.

- A new revenue stream built on turning waste into value, without increasing your environmental footprint.

With Lithium Harvest, you're not just participating in the green energy transition but helping lead it.

Surge Ahead With DLE From Produced Water

The environmental and operational advantages of extracting lithium from produced water are clear. But how does this revolutionary approach compare to conventional methods such as hard rock mining and evaporation ponds?

By examining the key differences, it becomes evident why Lithium Harvest’s solution is the superior choice for oil and gas companies seeking to enhance profitability and environmental stewardship. Together, we can lead the way in lithium extraction.

Lithium Harvest Solution |

Traditional DLE |

Solar Evaporation Brine Extraction |

Hard Rock Mining |

|

|---|---|---|---|---|

| Lithium feedstock | Produced water/geothermal brine | Continental brine | Continental brine | Rock / spodumene |

| Project implementation time | 12-18 months | 5-7 years | 13-15 years | 10-17 years |

| Lithium carbonate production time | 2 hours | 2 hours | 13-24 months | 3-6 months |

| Lithium yield | >95% | 80-95% | 20-50% | 40-70% |

| Average footprint per mt of LCE | 61 ft² | 172 ft² | 39,352 ft² | 3,605 ft² |

| Environmental impact | Minimal | Minimal | Soil and water contamination | Soil and water contamination |

| Freshwater consumption per mt of LCE | 22,729 gallons | 26,417 gallons | 118,877 gallons | 20,341 gallons |

| CO₂ footprint per mt of LCE | Neutral | 2.5 tonne | 3.1 tonne | 20.4 tonne |

| Average invested capital per mt of LCE | $17,100 | $62,500 | $34,000 | $60,000 |

| Average cost per mt of LCE | $3,647 | $6,000 | $6,400 | $7,000 |

Lithium Harvest Solution

Traditional DLE

Solar Evaporation Brine Extraction

Hard Rock Mining

Innovative Solution for DLE From Produced Water

Lithium Harvest: Pioneering sustainable lithium extraction through advanced water treatment and DLE integration.

At Lithium Harvest, we’re pioneering sustainable lithium extraction by combining Direct Lithium Extraction (DLE) technology with decades of water treatment expertise. Our innovative approach allows us to extract lithium efficiently from produced water while ensuring responsible water management throughout the process.

As water treatment specialists, we focus on minimizing environmental impact through carbon-neutral, energy-efficient solutions. By seamlessly integrating DLE with advanced water treatment, we’re committed to delivering high-purity lithium without compromising sustainability or environmental stewardship.

Future Outlook - Pioneering a Greener, More Sustainable Future

As demand for lithium continues to surge, the world faces a critical challenge: how do we meet this need without harming the planet? The call for sustainable, locally sourced lithium has never been louder.

The oil and gas industry is in a unique position to lead. With existing infrastructure and access to lithium-rich produced water, operators can drive the green energy transition. Lithium Harvest’s extraction solution helps turn a costly byproduct into a valuable resource while slashing environmental impact.

The future of lithium extraction is circular: repurposing waste, conserving water, and minimizing emissions.

Are you ready to be part of the solution?

Produced Water Treatment

You may also be interested in: